the stormproof® 75 Gpm system is ideal for...

Equipment Yards

Metal Recyclers

Auto Dismantlers

Fabrication and Machining Shops

Logistics and Warehouse Yards

Waste Handling Sites

Small to mid-sized industrial facilities

Facilities with limited space

Designed to reduce common igp exceedances

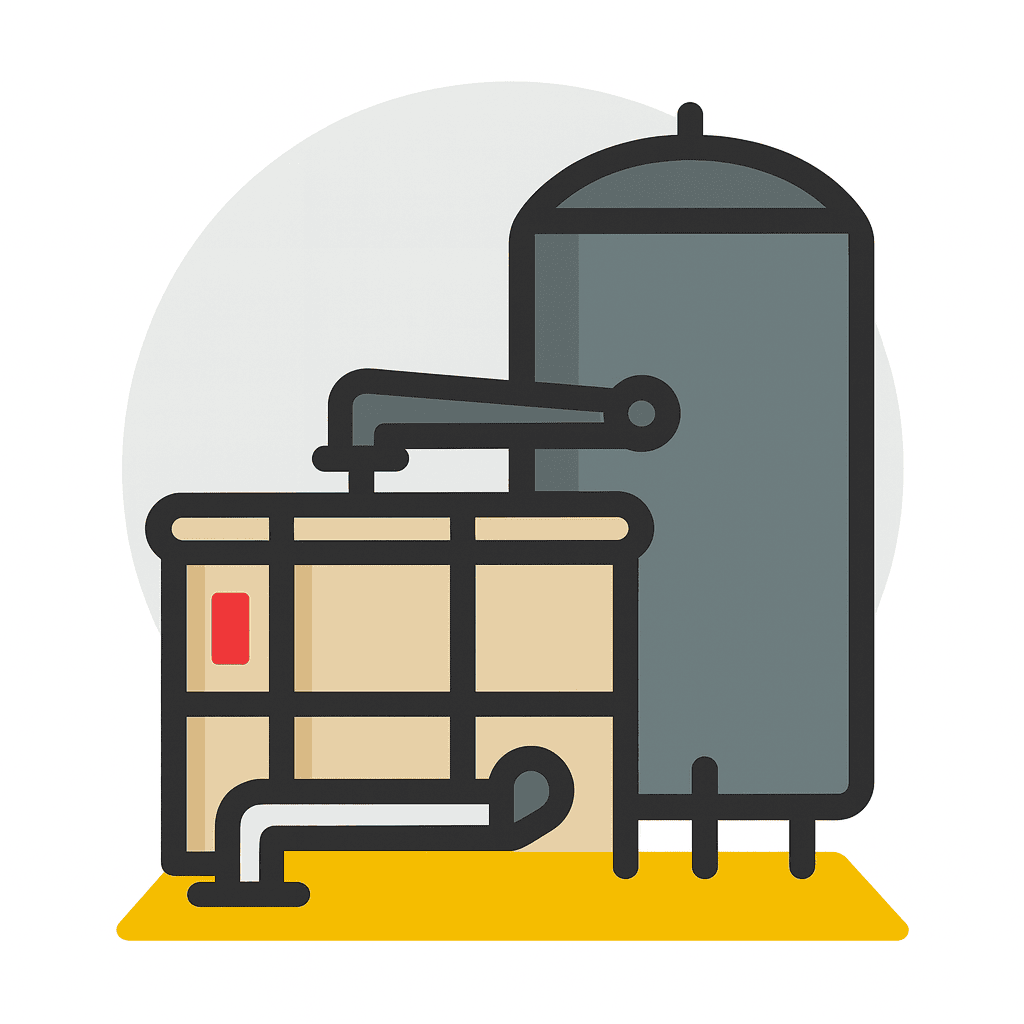

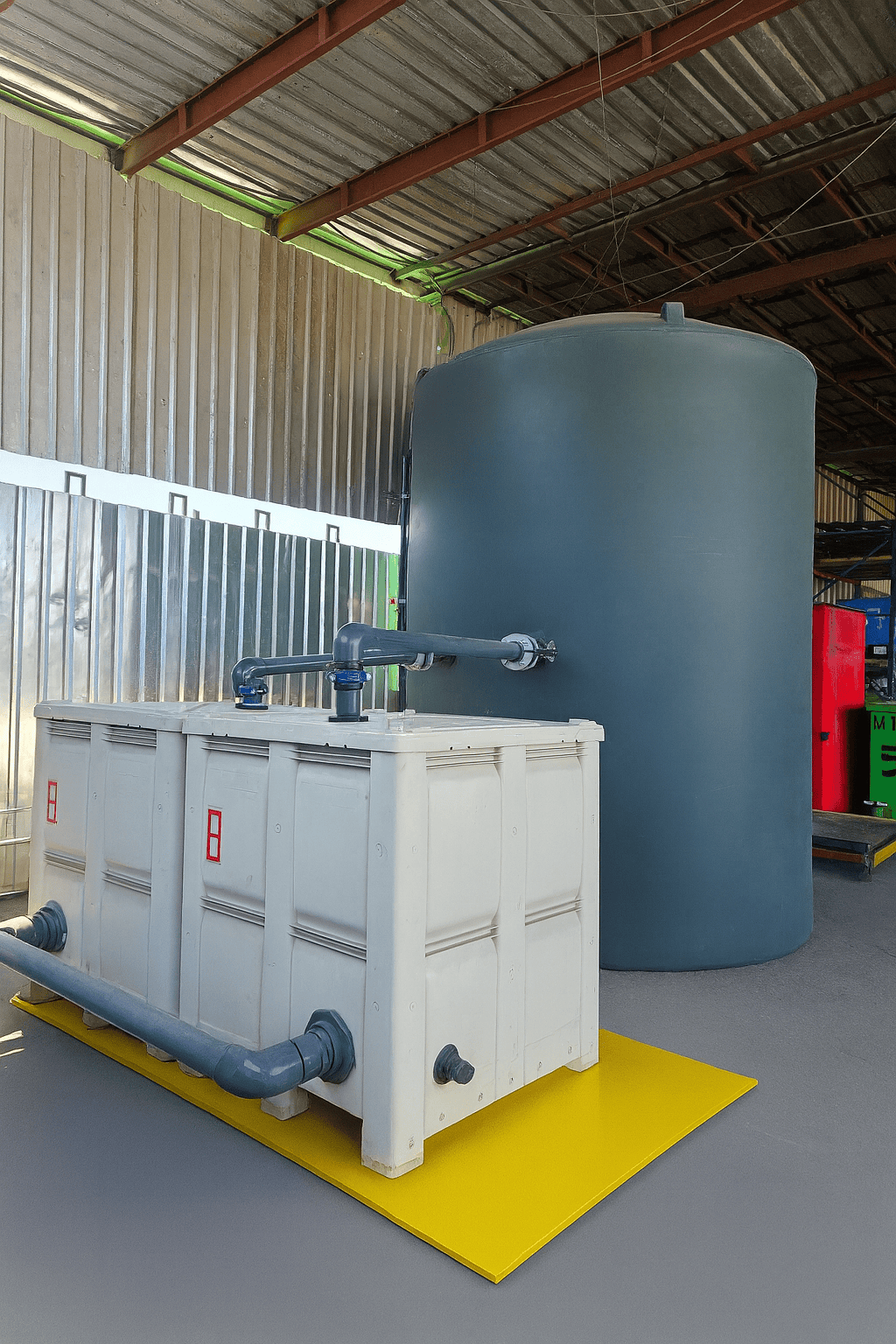

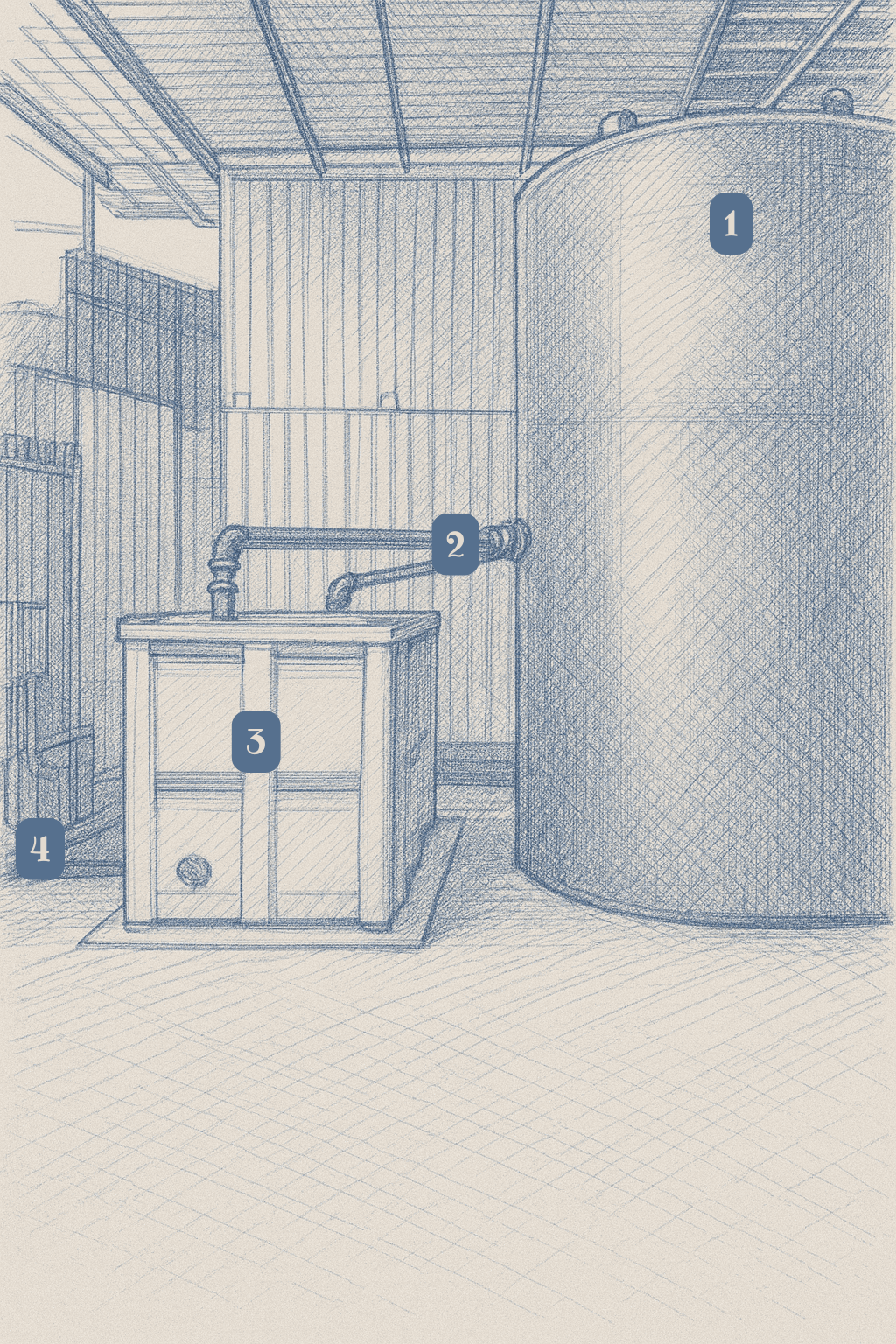

how the system works

A complete treatment system engineered for simplicity and performance.

1. Collection & Conditioning (Reaction Tank)

Water enters the large reaction tank where flow is equalized and solids begin to settle. This creates a stable, consistent feed to the filtration stage. The tank’s float-controlled pump delivers water only when the system is ready, preventing surges and maintaining steady treatment rates.

2. Flow-Control Valve

After leaving the reaction tank, water passes through a flow-control valve that regulates the treatment rate. This ensures optimal contact time with each filtration stage and maintains reliable 75 GPM performance.

3. Filtration – Media Totes

Water enters the treatment totes through a top-entry connection. Inside this chamber, larger sediment, debris, and suspended solids are captured. These totes contain a layered filtration media system, including:

- Sediment control layer

- Oil-absorbent media

- MetalPROOF™ metal-binding media

Together, these layers target fine sediment, hydrocarbons, and dissolved metals, delivering high-efficiency treatment in a compact footprint.

4. Passive Gravity Discharge

After passing through the media layers, treated water exits the outlet pipe consistently and cleanly. Discharge quality typically meets or exceeds IGP benchmark levels, providing compliance-ready performance with minimal operator attention.

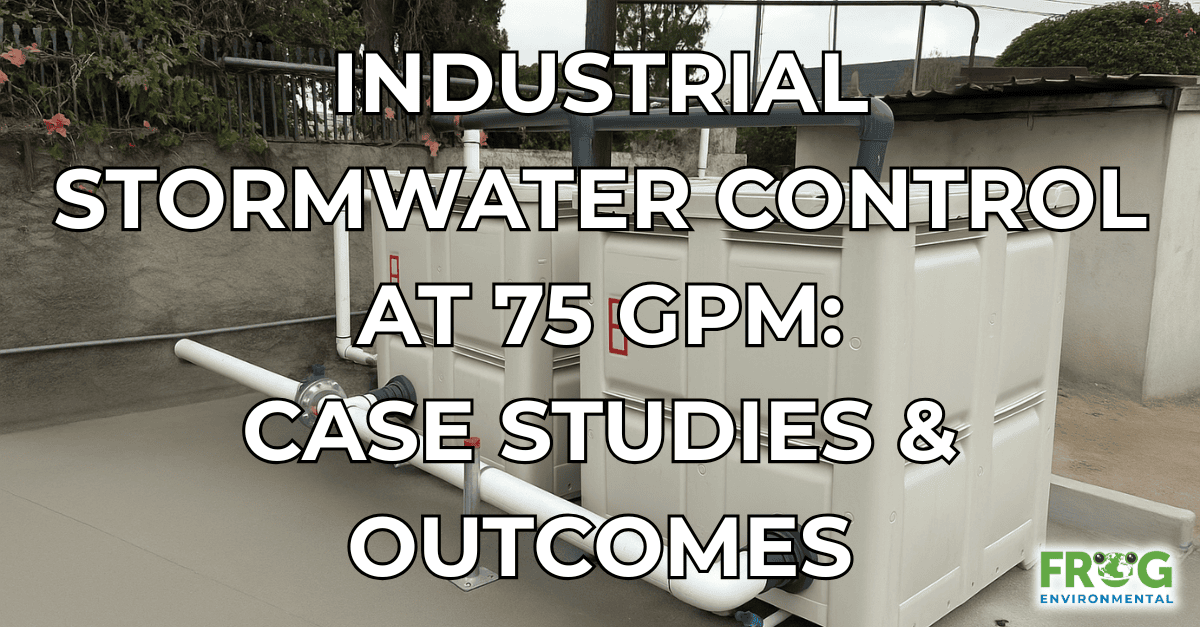

Why Choose the 75 GPM StormPROOF® System?

See how our 75 GPM Stormwater Treatment System delivered measurable pollutant reductions and achieved compliance with CA IGP Numeric Action Levels in real-world industrial applications.

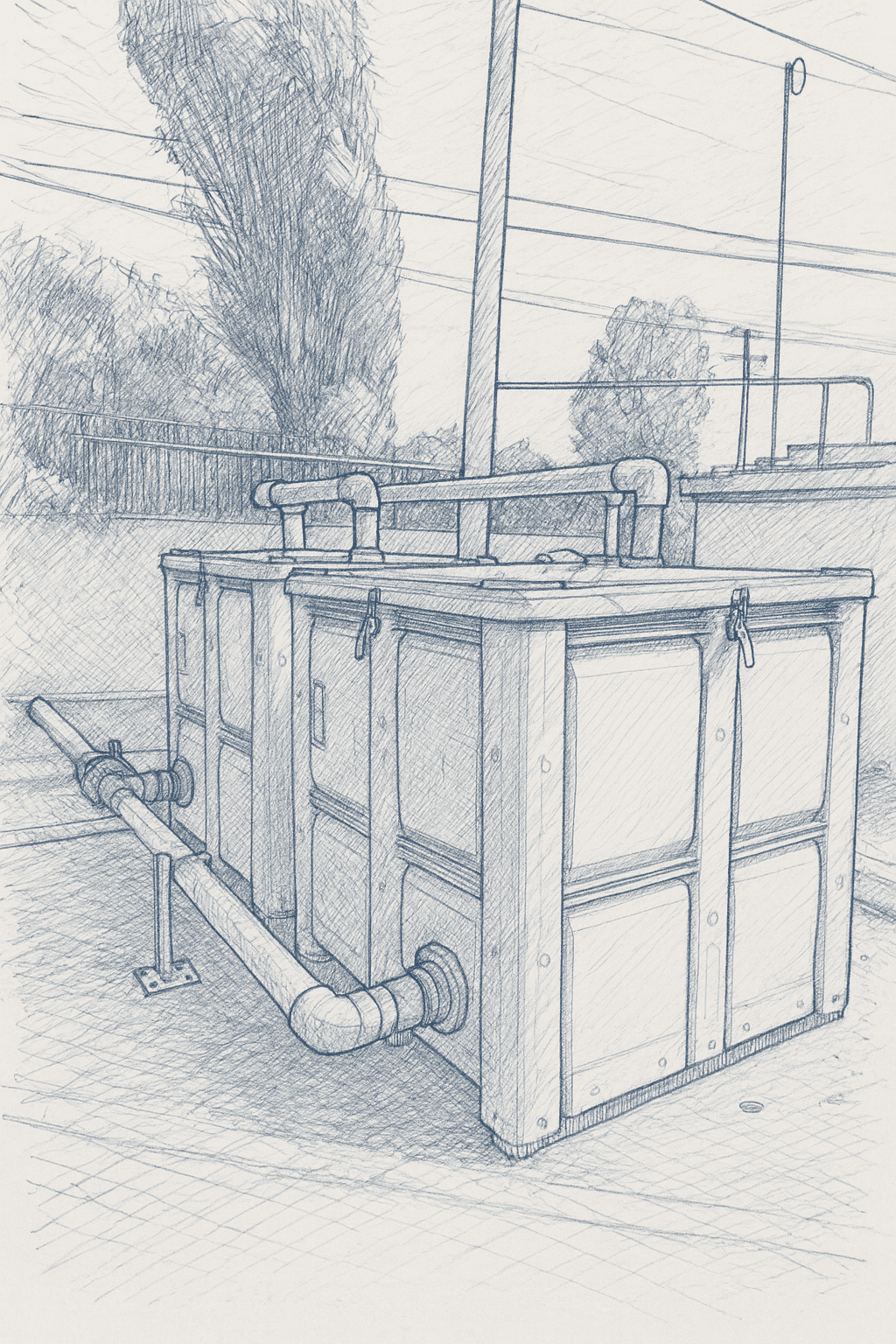

Available Configurations

2 Totes With Media

Only

2 Totes with Pumps, Controls and 5,000 Gallon Storage