Designed to reduce exceedances. Built to support long-term IGP compliance.

Frog Environmental provides engineered stormwater treatment systems for industrial facilities facing persistent benchmark or Numeric Action Level (NAL) exceedances. Our StormPROOF® treatment systems are custom-designed to target site-specific pollutants, improve sample results, and help facilities regain regulatory confidence under California’s Industrial General Permit (IGP).

These are not off-the-shelf filters. Each system is engineered based on your site conditions, drainage area, flow rates, and pollutant profile.

When Stormwater Treatment Systems Are Needed

- Structural and non-structural BMPs are no longer reducing pollutant levels

- Benchmark or NAL exceedances persist after corrective actions

- Level 2 ERA requirements call for engineered solutions

- Metals, nutrients, oil & grease, or high TSS loads cannot be controlled at the source

- Facilities need a defensible, long-term compliance solution

StormPROOF® Engineered Treatment Systems

- Total Suspended Solids (TSS)

- Oil & Grease

- Dissolved and particulate metals

- Nutrients (nitrogen-focused configurations)

- Site-specific industrial pollutants

Available Treatment System Options

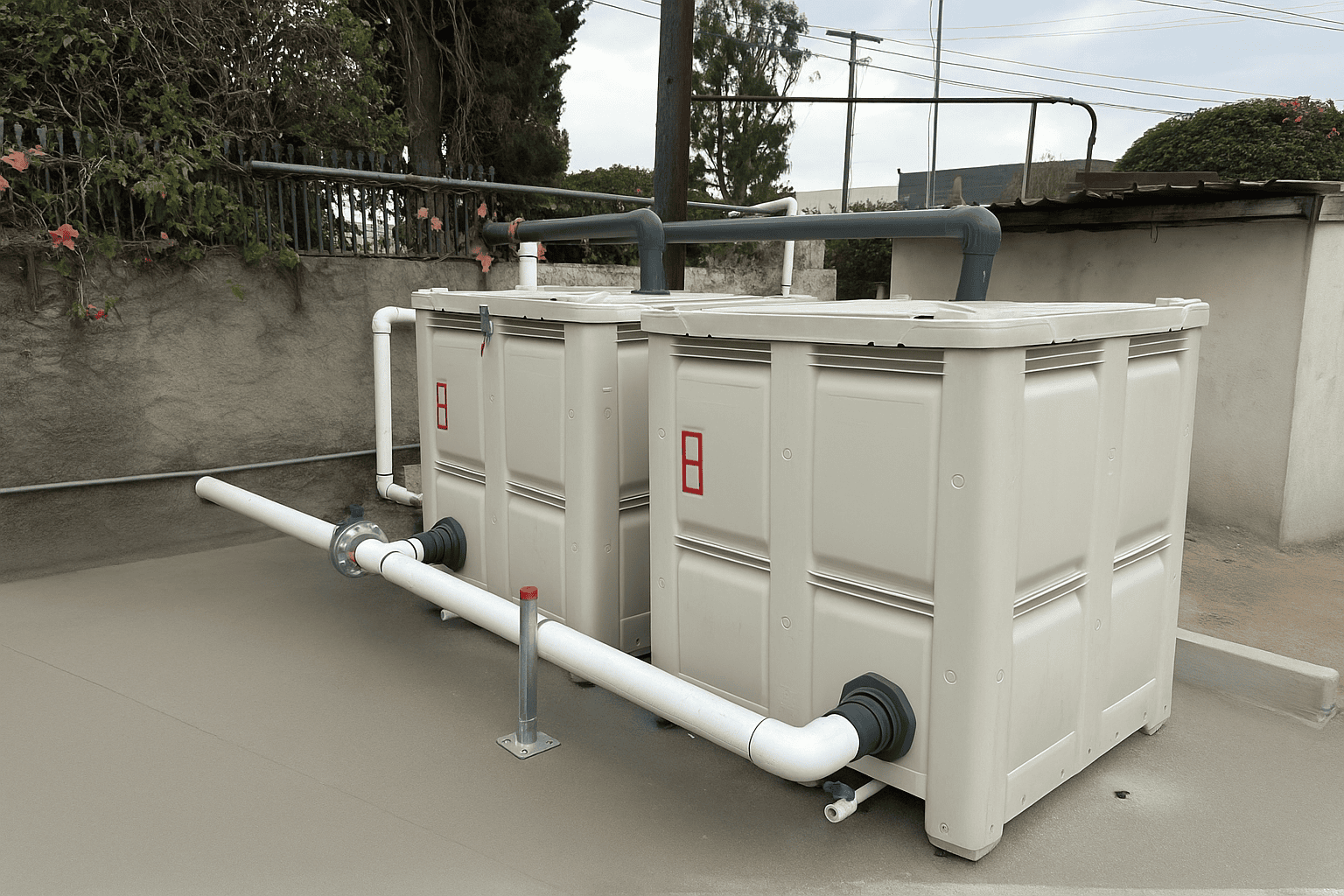

StormPROOF® 75 GPM Gravity System (SPG)

- Small to mid-sized drainage areas

- TSS, oil & grease, and metals reduction

- Sites requiring minimal maintenance and power-free operation

- Gravity-fed design

- Multi-stage filtration media

- Compact footprint

- Engineered for permit compliance support

StormPROOF® Pressurized MetalPROOF System (SPM)

High-performance treatment for dissolved and particulate metals.

The MetalPROOF system is designed for facilities struggling with persistent metals exceedances. Using pressurized treatment and specialized media, this system targets both dissolved and particulate metal fractions.

Best for:

- Facilities with copper, zinc, lead, or other metal exceedances

- Higher flow rates and pollutant concentrations

- Sites requiring advanced treatment performance

Key Features:

- Pressurized system design

- Advanced metals-specific filtration media

- Scalable flow capacities

- Engineered to support ERA and NAL compliance

StormPROOF® NitrogenPROOF

System (SPN)

Targeted nutrient reduction for sensitive receiving waters.

The NitrogenPROOF system is engineered to address nitrogen loading where nutrient exceedances or TMDLs apply. This system is customized based on nitrogen species and site discharge requirements.

Best for:

- Facilities with nitrogen or nutrient exceedances

- Sites discharging to impaired or sensitive waters

- Regulatory environments requiring nutrient controls

Key Features:

Nitrogen-targeted treatment media

Custom system configurations

Designed for regulatory-driven nutrient reduction

Scalable System Sizing

StormPROOF® systems are available in multiple flow configurations to match your site. Higher flows are available through modular design.

Each system is sized based on drainage area, rainfall intensity, pollutant loading, and permit requirements.

Flow Capacity:

75 gallons per minute (GPM)

System Footprint:

10 ft x 18 ft

Ideal for Site Size:

0.5 – 2 acres

Use Case:

Small to mid-sized facilities looking for a compact, effective stormwater treatment solution. Perfect for first-stage pollutant removal of TSS and O&G.

Flow Capacity:

100 gallons per minute (GPM)

System Footprint:

10 ft x 26 ft

Ideal for Site Size:

1 - 4 acres

Use Case:

Mid-sized facilities requiring a balance of performance and footprint. Treats TSS, O&G, and select metals efficiently.

Flow Capacity:

250 gallons per minute (GPM)

System Footprint:

12 ft x 36 ft

Ideal for Site Size:

2.5 – 7 acres

Use Case:

Larger industrial sites with complex discharge needs. Designed to accommodate higher flow volumes and multi-stage treatment, including metal and nutrient removal with system upgrades.

Flow Capacity:

500 gallons per minute (GPM)

System Footprint:

15 ft x 60 ft

Ideal for Site Size:

4+ acres

Use Case:

High-demand industrial operations requiring robust, large-scale stormwater treatment. Best suited for heavily regulated sites, and compatible with all StormPROOF® upgrades for metals, nutrients, and phosphorus.

Key Features of StormPROOF® Systems

Customized solutions designed using site data and discharge permits

Patented BAT technology ensures top-tier treatment efficiency

Multi-stage filtration: pre-treatment, primary filtration, and polishing

Reduce liability by avoiding exceedances, enforcement actions, and lawsuits

Included Services with Every System

StormPROOF® isn’t just equipment—it’s a complete stormwater management solution. Every system includes:

Site-specific engineering, design drawings, and calculations

Equipment sizing and selection

Delivery, installation, and commissioning

Ongoing maintenance options available

Additional

Considerations

- While our systems are turnkey, some site conditions may require:

Local permits (City/County)

Infrastructure upgrades for power or water access

On-site construction, seismic retrofits, or drainage improvements

Our team will help identify and plan for these requirements during the design phase.

How Advanced Stormwater Treatment Upgrades Protect Compliance

Outdated BMPs can lead to stormwater exceedances. Learn how advanced treatment systems and targeted upgrades improve compliance and performance.