Best Management Practices (BMP) FAQs

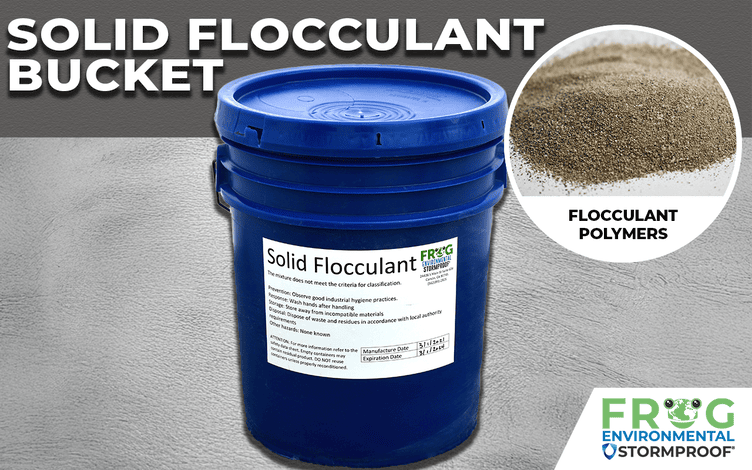

Solid Flocculant

1. WHAT IS THE EXPECTED LIFESPAN OF SOLID FLOCCULANT?

Flocculant is single-use once deployed. However, one bucket can cover multiple storm events depending on water volume. Use at least 6 lbs per acre and do not exceed 20 lbs per acre (see attached Flocculant Instructions).

2. How much and where should flocculant be applied?

Apply flocculant upstream of wattles or socks so runoff flows through both. See deployment diagram for placement relative to drains and flow paths. Pre-deployment before a storm is best, but reactive application can still reduce TSS.

3. Do flocculants reduce pH drift?

Most flocculants target turbidity (cloudiness) and metals, not pH.

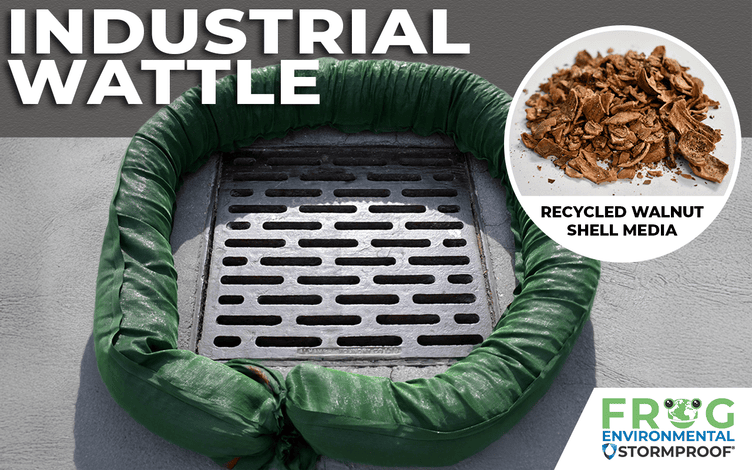

Industrial Wattles

1. What’s the lifespan of industrial wattles in real-world conditions?

6–18 months depending on UV exposure, pollutant load, and water volume. Replace at least once per stormwater year; high-risk sites often benefit from biannual replacement.

2. How should industrial wattles be stored?

Keep in a dry, cool area. Avoid sun and moisture exposure. Do not stack heavy items on top of them.

3. Can I leave industrial wattles out between storm events?

They can be redeployed but leaving them out will reduce lifespan. Remove from flow paths, store dry, and inspect before redeployment.

4. How many industrial wattles should I use per sampling point?

At least four industrial wattles per sampling point is recommended. Additional wattles may be used for high flows or steep slopes.

5. How far apart should industrial wattles be when leading to a sampling point?

Spacing depends on slope and flow velocity. As a general rule, 10–25 feet apart on slopes, closer if flow velocity is high.

6. What if water is flowing around the industrial wattles instead of through them?

Overlap ends to prevent bypass flow. Redirect flow using additional wattles if necessary.

7. Do we still need industrial wattles if inlet filters are installed?

Yes. Wattles act as the first line of defense by capturing larger debris and sediment, extending the lifespan of inlet filters.

8. Can industrial wattles withstand forklifts, trucks, or heavy traffic?

Not reliably. They should be placed away from vehicle paths or protected with barriers. Forklift or truck traffic will crush and degrade them.

9. If industrial wattles are only deployed during rain events, will it extend shelf life?

Yes. Limiting deployment to storm events reduces UV and physical wear, extending usable life.

10. If replaced only biannually, how ineffective will wattles be by year two?

Effectiveness drops significantly after 12 months of use. Degradation, saturation, and UV exposure mean performance is unreliable in year two.

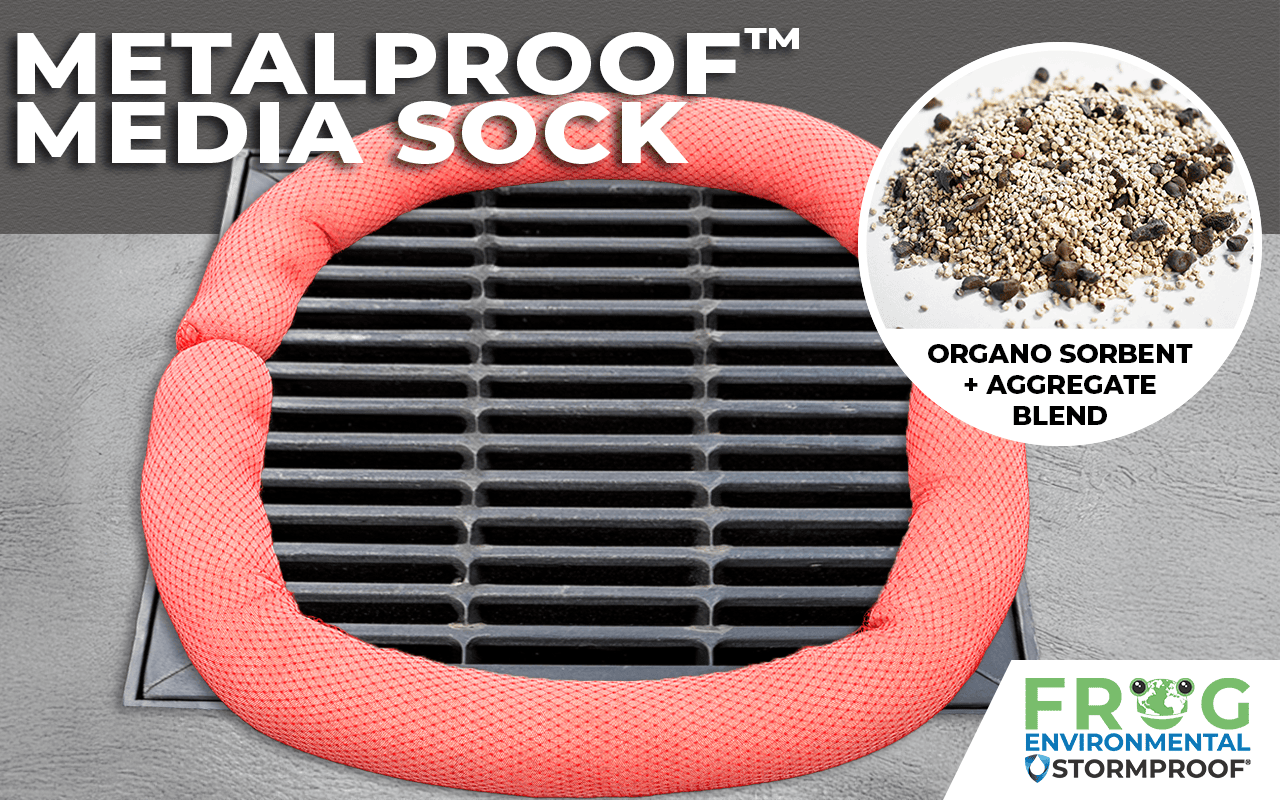

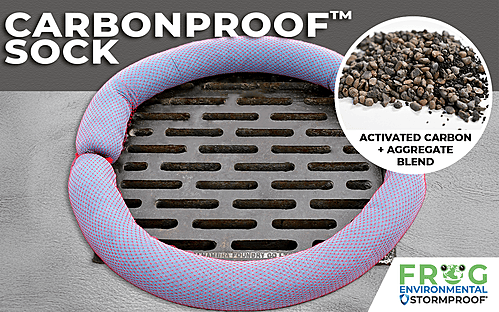

MetalPROOF™ and CarbonPROOF™ Media Socks

1. What’s the lifespan of Media socks?

6–12 months depending on flow and pollutant load. Replace annually or sooner if saturated.

2. How should Media socks be stored?

The same as wattles; store in a cool, dry, shaded area. Keep sealed until deployment.

3. How many Media socks should be used with a wattle at a sampling point?

At least five media socks in addition to four industrial wattles are recommended for effective treatment. Pollutant type (oil, metals, COD/BOD) determines media selection.

4. Do Media socks help reduce pH, COD, or BOD?

a. CarbonPROOF™ Socks: Reduce COD and BOD.

b. MetalPROOF™ Socks: Target metals.

c. pH Control: Standard socks do not buffer pH; specialized amendments are required.

5. How many oil sheen or Media socks should be placed per industrial wattle?

At least 1 media sock per wattle is the minimum recommended; more may be needed if lab results show high exceedances.

6. Can the media in downspout barrels be cleaned?

Yes, media can be removed, cleaned and reused. Media socks should be replaced annually for reliable performance.

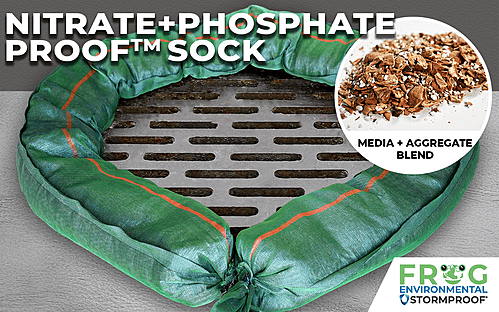

Nitrate+PhosphatePROOF™ Socks

1. What’s the lifespan of Nitrate/Phosphate Socks?

Typically 6–12 months depending on flow volume, pollutant load, and storm frequency. Sites with nutrient exceedances should monitor quarterly and replace when saturated.

2. How should Nitrate/Phosphate Socks be stored?

1. The same as wattles; store in a cool, dry, shaded area. Keep sealed until deployment.

3. How many Nitrate/Phosphate socks should I use per sampling point or wattle?

At least two nutrient socks in addition to an industrial wattle are recommended. Heavier pollutant loads may require additional units or staged installation.

4. Do these socks help reduce pH, COD, or BOD?

Nutrient socks specifically target nitrogen and phosphorus compounds. They do not directly buffer pH or reduce COD/BOD, but they complement carbon socks when multiple exceedances are present.

5. Can nutrient socks be combined with other socks in one setup?

Yes. They are often used in combination with carbon, oil sheen, or MetalPROOF™ socks. Deployment should be tailored to site-specific pollutant exceedances.

6. How should used nitrate/phosphate socks be disposed of?

General refuse disposal is acceptable unless lab results show hazardous pollutant concentrations. Confirm with your waste hauler if exceedances are high.

Effectiveness and Disposal

1. Are BMPs made with hazardous or leachable materials?

No. BMPs are made with inert, non-hazardous materials. Spent BMPs can be disposed of as general refuse unless they have captured significant hazardous material (check lab results/site conditions).