At Frog Environmental, we don’t just sell BMPs, we engineer and build them in-house to solve real industrial stormwater challenges. From wattles to media socks targeting heavy metals, hydrocarbons, and nutrients, every product is designed for performance, durability, and permit compliance. Whether you're battling high TSS, dealing with oil sheen, or preparing for a Level 1 or 2 ERA response, our in-house BMPs provide flexible, site-specific solutions. In this post, we’ll walk through each product, show you what’s inside, and explain how to deploy them effectively during rain events.

UV Resistant Industrial Wattle

What it is: Heavy-duty sediment control barriers used as check dams, flow slowers, or perimeter containment.

What it's made of: Filled with recycled walnut shells and encased in UV-resistant mesh for durability and flexibility.

How it's used: Ideal for trapping sediment and slowing flow across swales or inlets.

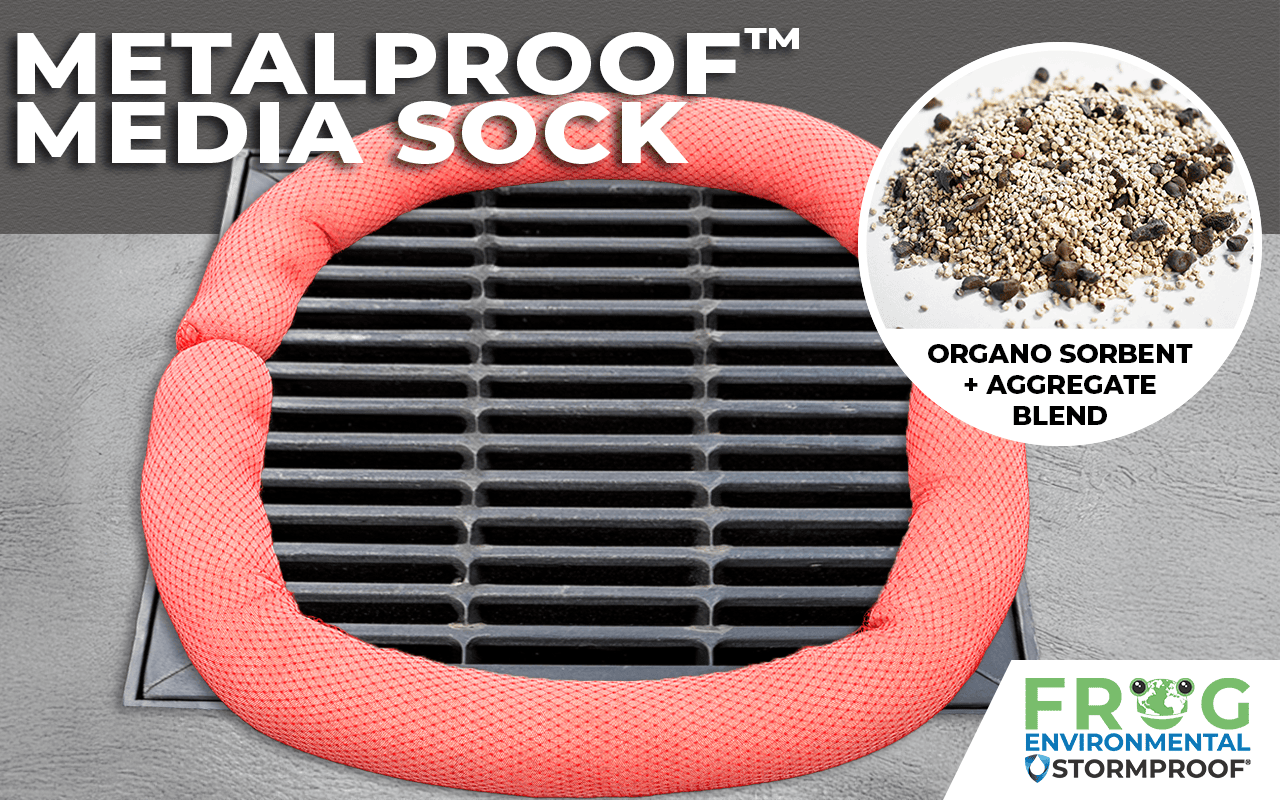

MetalPROOF™ Media Sock

What it is: Media-filled sock engineered to filter dissolved heavy metals such as Copper, Zinc, or Lead from stormwater.

What it's made of: A 2:1 ratio of Organo Sorbent and aggregate blend inside a durable outer sock designed for industrial drains.

How it's used: Place across sheet flow after Industrial Wattles to reduce metal concentrations before discharge.

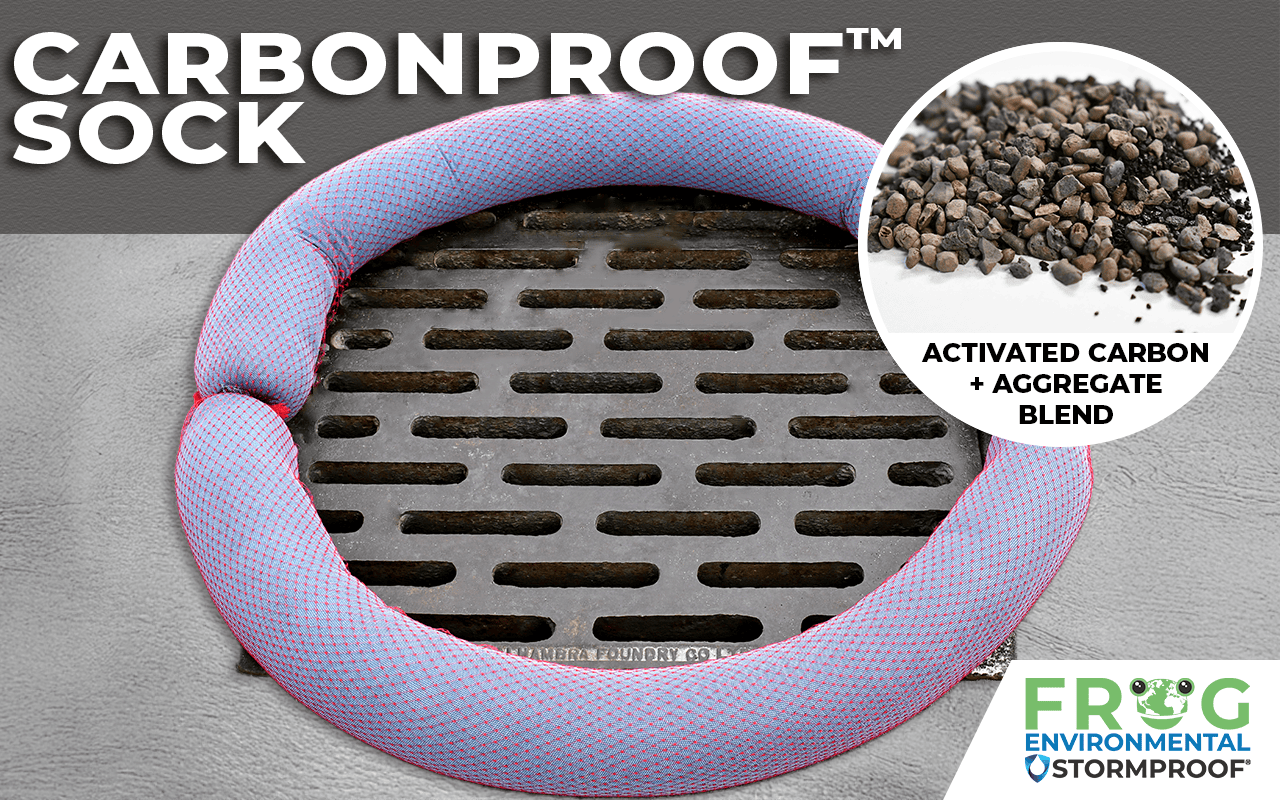

CarbonPROOF™ Sock

What it is: Activated carbon sock targeting oils, greases, and organic compounds.

What it's made of: A 2:1 ratio of activated carbon (high-porosity filtration) and lightweight aggregate (improves TSS capture.)

How it's used: Effective at intercepting hydrocarbons from runoff before leaving the site. Deploy behind a wattle for maximum pollutant removal.

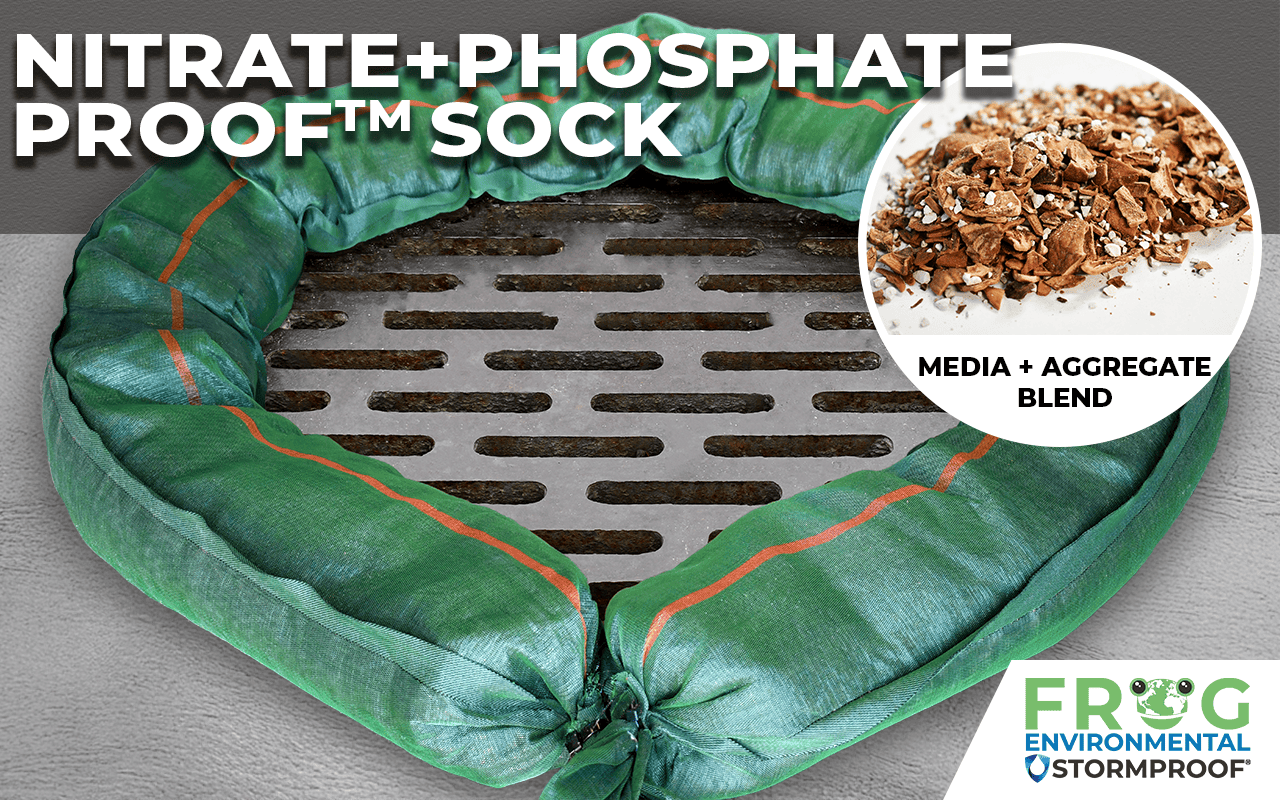

Nitrate + PhosphatePROOF™ Sock

What it is: Targets nutrient pollution from green waste, agriculture and fertilizers.

What it's made of: A 2:1 ratio of an anion-selective media and lightweight aggregate.

How it's used: Specifically removes Nitrates and Phosphates along with other anions, like sulfates from runoff.

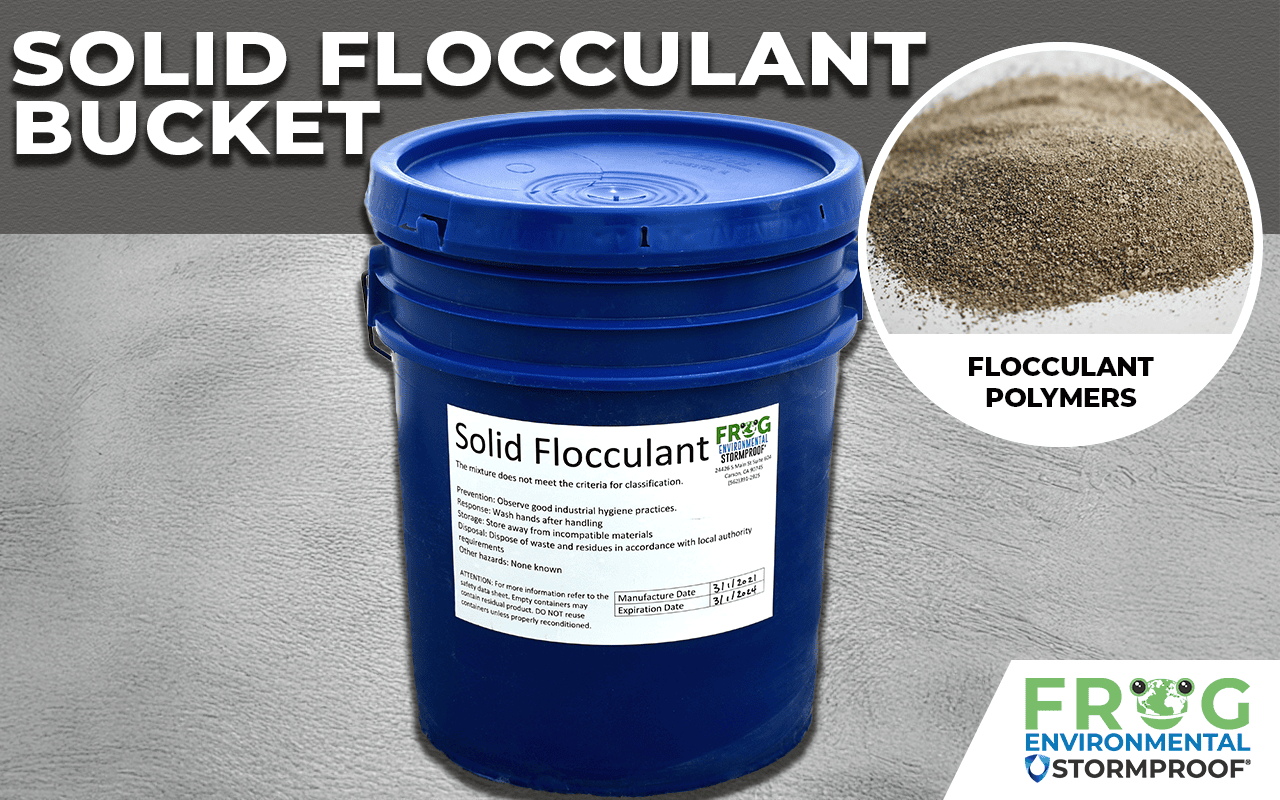

Solid Flocculant Bucket (2 or 5 Gallon)

What it is: Solid-form flocculant to destabilize and remove suspended solids (TSS).

What it's made of: Flocculant polymers in 2 or 5 gallon buckets.

How it's used: Sprinkle to upstream water to coagulate fine sediment, enabling quicker settlement.

See how our Flocculant works in real time! Click to watch our demo.

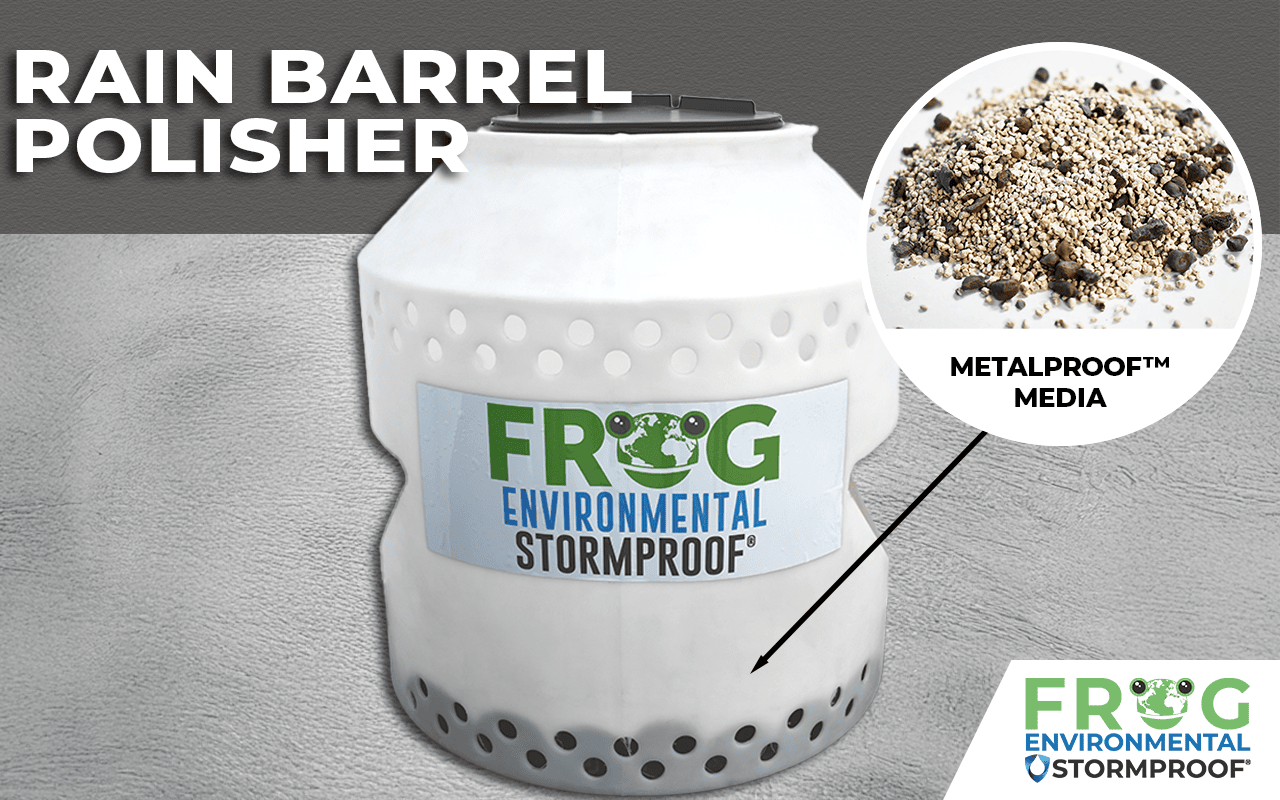

Rain Barrel Polisher

Function: Inline or end-of-pipe polishing for persistent pollutants.

How it's used: Attach to downspouts, or sump pump outlets for final-stage filtration.

Advantages: Compact, scalable, and simple to maintain.

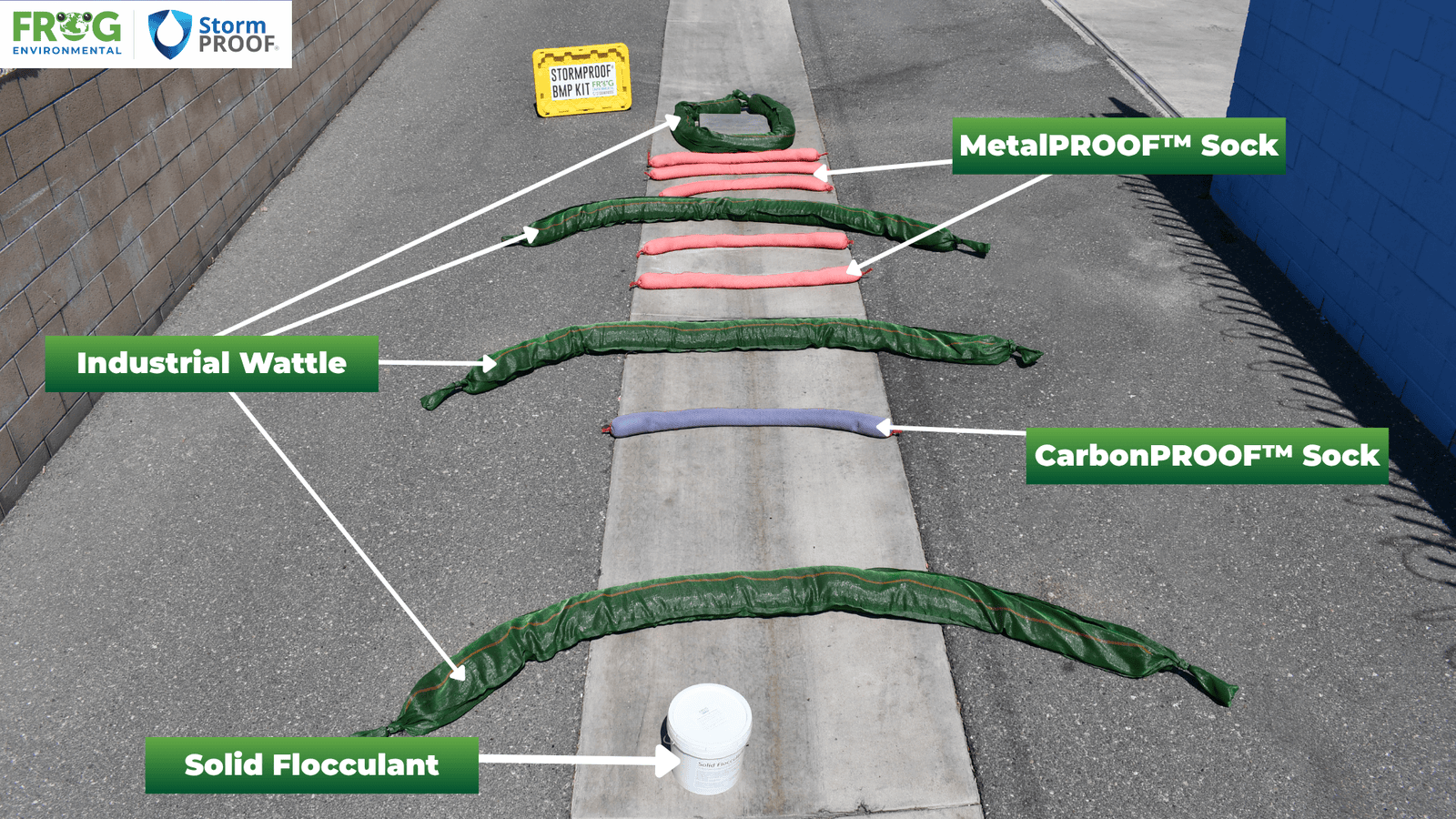

BMP Deployment Example for a Rain Event

Refer to the photo above: units are arranged perpendicular to flow across an asphalt or concrete swale.

1. First layer: Industrial Wattle Barrier

– Install the green Industrial Wattle across the path of incoming runoff to trap sediment and control flow.

2. Second layer: Specialized Sock

– Just downstream, place either the MetalPROOF™ Sock (for metal removal) or the CarbonPROOF™ Sock (for oil/organics). These sit between the Industrial Wattles to treat filtered flow.

3. Optional: Solid Flocculant

– Apply upstream if turbidity or fine sediment is an issue. It binds particles together for faster settling.

4. Top-off: Additional Wattles

– Additional Industrial Wattles furthers flow control, ensuring any stray sediment or runoff passes through the media socks.

This tiered setup allows water to slow → settle → filter in successive stages, maximizing pollutant removal before runoff exits your site.